How to Use a Manometer for Gas Leaks

When there’s a suspected gas leak, gas fitters use a tool called a manometer to accurately detect the fault. But what exactly is a manometer, and how does it work?

Simply put, a manometer is a device that is used to measure pressure. A traditional device is U-shaped, hence why it is sometimes called a U-tube manometer. However, with modern technology comes change, and it’s common to see digital manometers in practice.

So What Does A Manometer Do?

Manometers show a pressure drop in the gas line, indicating that there is a leak present. We’ll go into further detail on how exactly that works in a moment.

First, there are two main types in use, the analogue manometer (or U-tube manometer) and digital manometer. There are also slight variations on the analogue, including inclined, absolute and hydronic manometers. We won’t specifically touch on them in this article.

Without further ado, let’s take a look at how to use a manometer, and how it can uncover a gas leak.

Understanding Different Manometer Pressure Terms

When it comes to measuring pressure with a manometer, understanding the various pressure terms is crucial as each type of measurement serves a specific purpose in different applications:

- Differential pressure: Refers to the difference in pressure readings between two points in a system, indicating flow rate or level differences measured by a manometer.

- Atmospheric pressure: The pressure exerted by the air in the atmosphere; it serves as a reference point for other pressure measurements in manometers.

- Gauge pressure: The pressure within a system minus the atmospheric pressure; manometers typically measure gauge pressure when assessing fluid or gas systems.

- Absolute pressure: The total pressure within a system, obtained by adding the gauge pressure to the atmospheric pressure; it is measured from an absolute vacuum.

- Negative pressure: A pressure lower than the surrounding atmospheric pressure. In manometer terms, it shows that the system is under a vacuum relative to the atmosphere.

- Static pressure: The pressure exerted by a fluid at rest; in a manometer, it represents the potential energy available in the fluid due to its elevation or depth.

These terms collectively describe the different ways pressure can be understood and measured in various contexts using a manometer.

Analogue Manometers and Atmospheric Pressure

When talking about specialised equipment like a manometer, it is easy to get bogged down with the details. That’s not our goal. Rather it’s to provide easily absorbed information that gives a quick insight.

Analog manometers are one of the most common types of manometers on the market. They’re a U-shaped tube that contains fluid, typically either water or, in some cases, mercury. One end of the U tube is directly connected to the gas line while the other end remains open to external pressure. Some models are also open at both ends and can be capped.

Understanding U Tube Manometer Readings

When the manometer is connected to the gas line, the internal fluid should remain level on each side of the U, indicating balance as it reacts to gas pressure. The liquid will move, however, it should quickly settle if the gas pressure and air pressure are even.

However, if pressure is applied unevenly, then the fluid in one leg of the water column will be forced down. The difference between the two sides of the U reveals additional positive pressure is pushing down, and there could be one of two reasons:

- If the liquid is higher on the open side, gas pressure is higher than air pressure

- If the liquid is higher on the closed side, air pressure is higher than gas pressure

With natural changes in atmospheric pressure, the reading can vary from time to time. That’s why accurate instruments are necessary for measuring any differential pressure.

Other designs like the well-type manometer and inclined manometer provide even more sensitivity and are especially effective at picking up smaller leaks.

Digital Manometer Accuracy

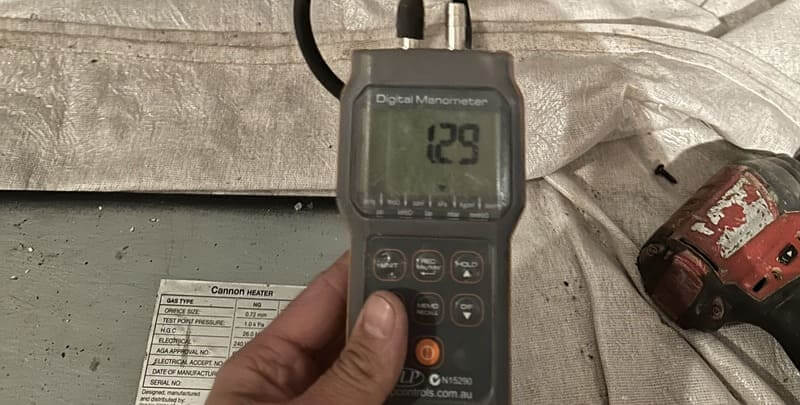

Technology has seen rapid growth in the accuracy of digital manometers, also known as electrical manometers. Not only can they detect a pressure drop, but they are also used to calibrate and commission gas appliances.

Digital manometers provide accurate readings with ease. Unlike the analogue manometer, a pressure transducer is used to create a result. The elastic component of the transducer detects external pressure levels and converts the energy into an electronic signal. A perfect reading is displayed instantaneously in pascals or psi.

There is a range of digital manometers on the market for specific uses, too.

For example, there is a hydronic manometer and data logger which is specially designed to balance hydronic heating and cooling systems. It provides accurate measurements for pressure differential, while it can independently reveal the pressure on both the low and high side at the same time.

Your Best Friend In Measuring Gas Pressure and Detecting Gas Leaks

All in all, having a high-quality instrument to measure differential pressure is the perfect way for a gas fitter to detect faults. Whether it’s analogue or digital, a manometer remains a leading tool used to measure gas pressure and therefore instrumental in gas leak detection.

Please note: This information is provided for advice purposes only. Regulations differ from state to state, so please consult your local authorities or an industry professional before proceeding with any work. See our Terms & Conditions here.